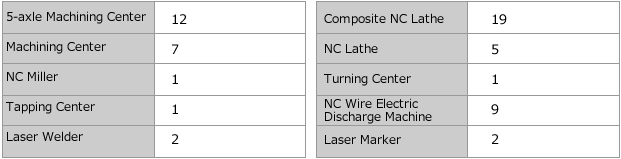

| Mechanical Equipment We constantly hold an aggressive approach towards investing in equipment, and have implemented 40 of the latest NC machine tools. The 7-axis 3 system control reverse-side composite machining NC lathe contains a bar material feeding device, and the 5-axis control machining center is equipped with a workpiece changer. This equipment is able to operate around the clock 24 hours a day. |

|

List of Primary Mechanical Equipment

|

5-axle Control Machining Center In addition to the three normal X, Y, and Z axes, the equipment is also able to control the calculated direction of the inclination or rotation. We also accommodate cutting requests related to complex shapes or elaborate cubic surfaces. In addition, because our products only require a single chucking for processes that require traditional secondary fabrication, we can provide a significant increase in precision and quality while, also greatly curving costs. |

| Temperature Control In 1995, we set up a production facility equipped with constant-temperature air conditioning in order to consistently produce products that can support even higher temperatures. Because we have installed 10 air intake ports, 16 air outtake ports and 4 temperature sensors in our 310ću production facility, we are able to maintain consistent temperatures with fluctuations of no more than ü}2 degrees. Although this equipment is top of the line, aiming for consistency in the size of our products and temperature regulation greatly helps keep our costs down. |

|

Saney Seiko Inc.

Asaka Office : 2-10-14 Senzui, Asaka, Saitama Prefecture 351-0024

TEL : 048-466-9551 / FAX : 048-463-9419

Copyright (C) Saney Seiko Inc . All Rights Reserved.